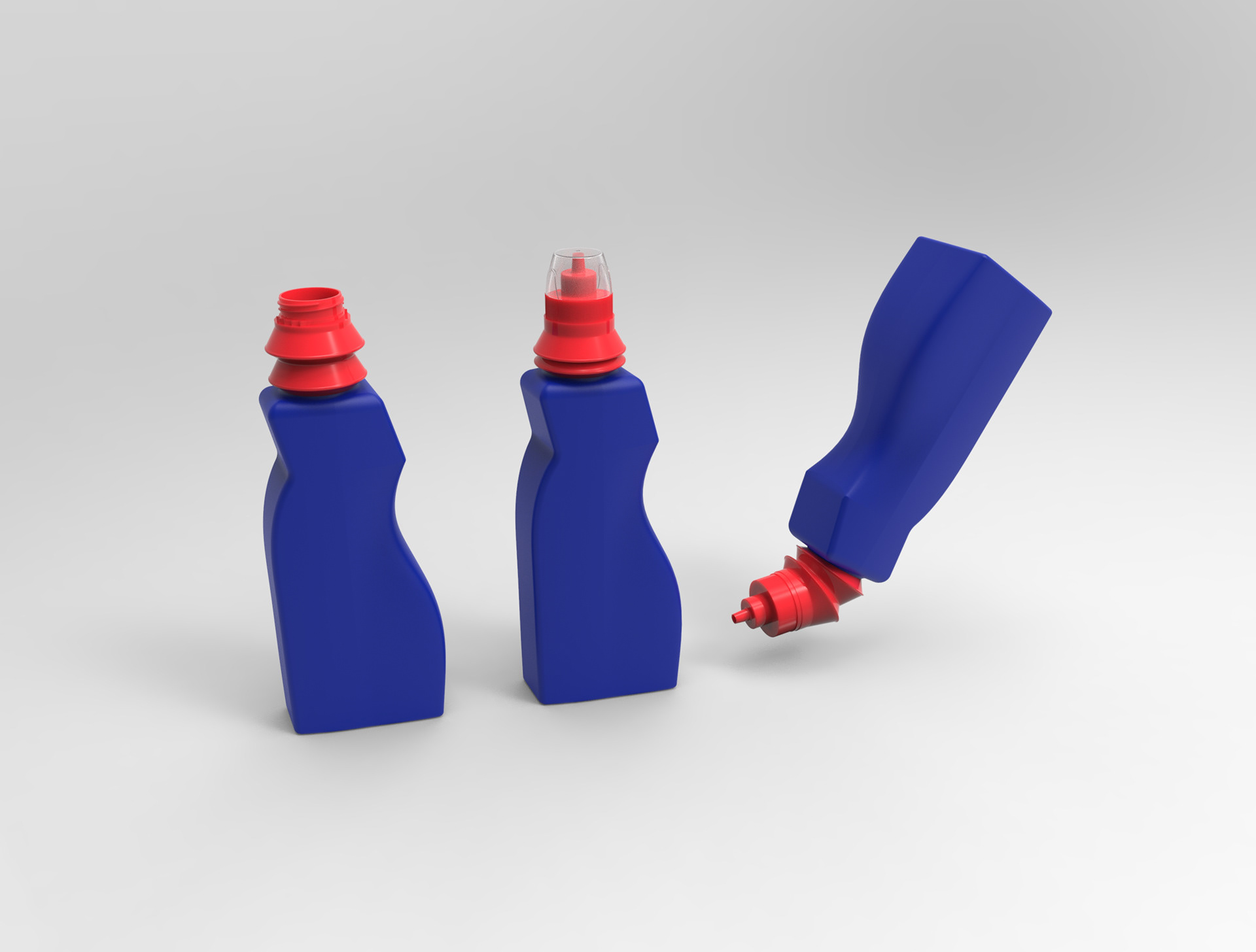

For this project we where approached by Orkla, a leading supplier of branded products to the grocery, large-scale household, specialist trade, pharmacy and the bakery market. Our task was to design a new bottle for Klorin, a toilet cleaning product. Some of the challenges we wanted to solve was to enable vertically aligned filling and application of closure. It had to be user friendly in the cleaning situation (ergonomic), have a child resistent closure, 750 ml fill volume and be suited for application of either label or shrink sleeve. For this project we focused on production and innovation. The bottles had to be produced using the manufacturing process "blow molding".

Groupwork with Agata Cypriak Vel Czupryniak and Clementine Rusten.

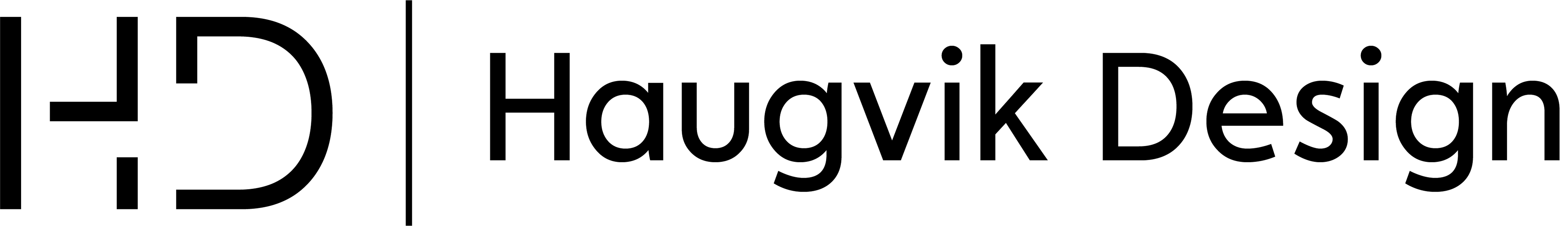

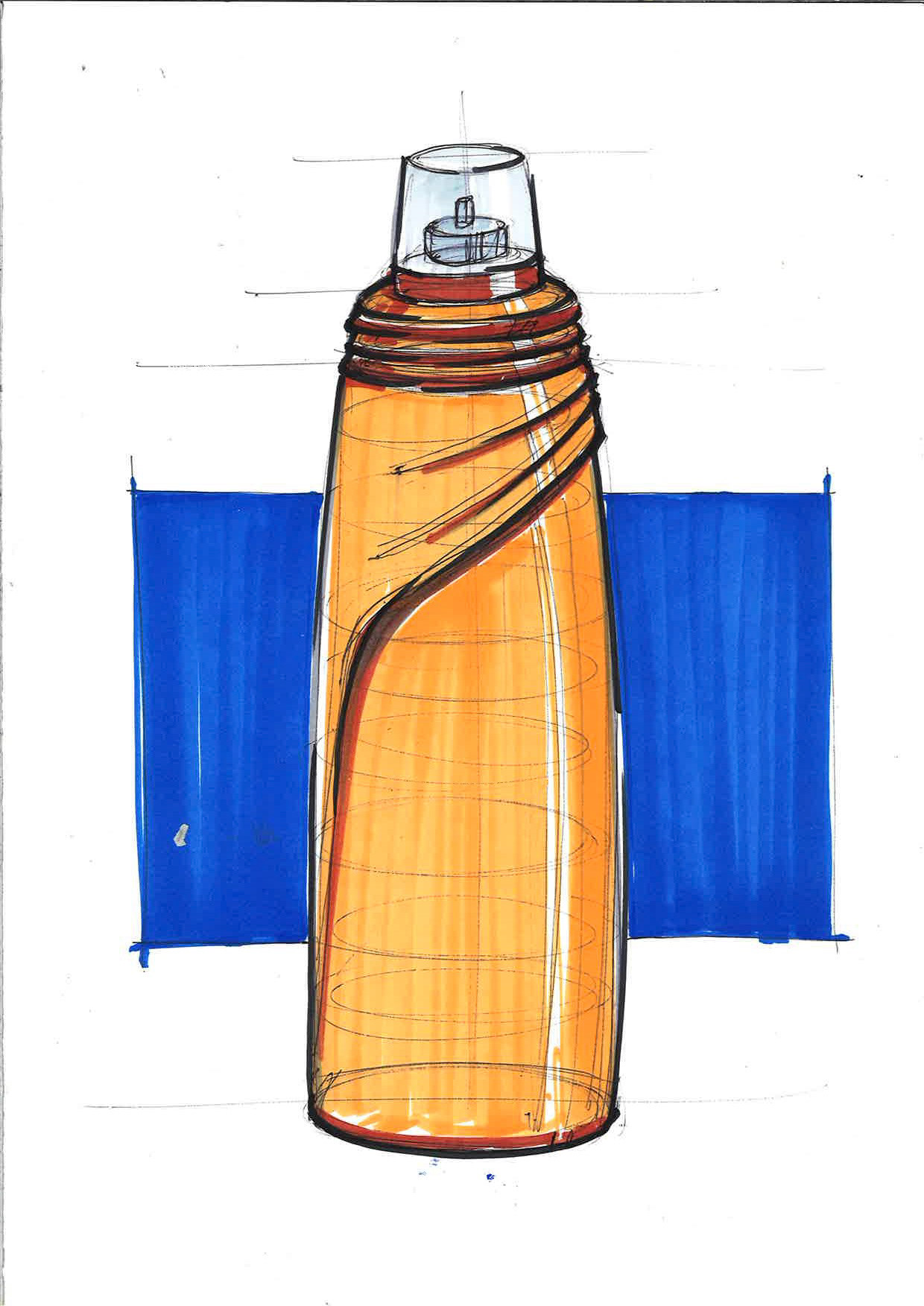

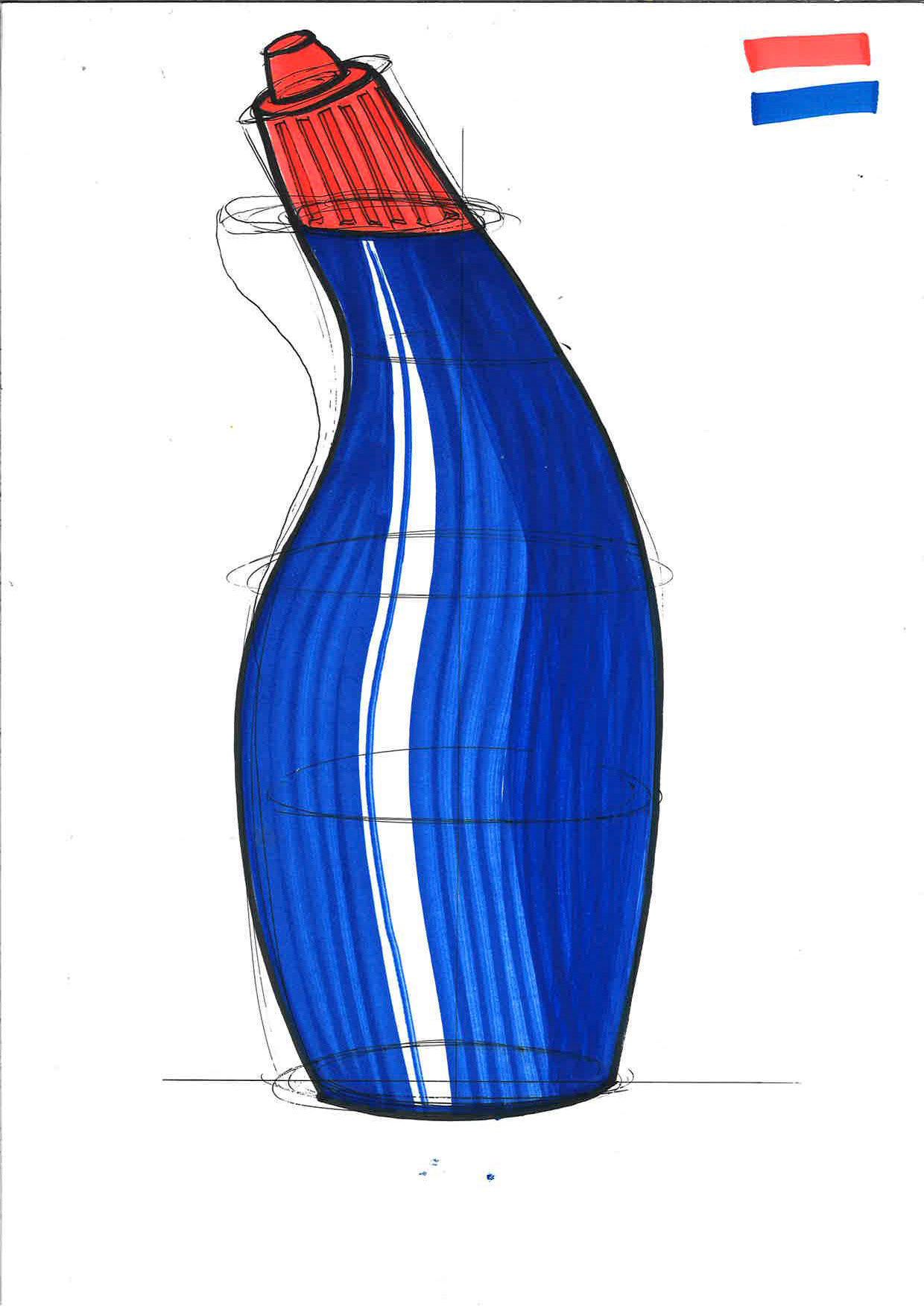

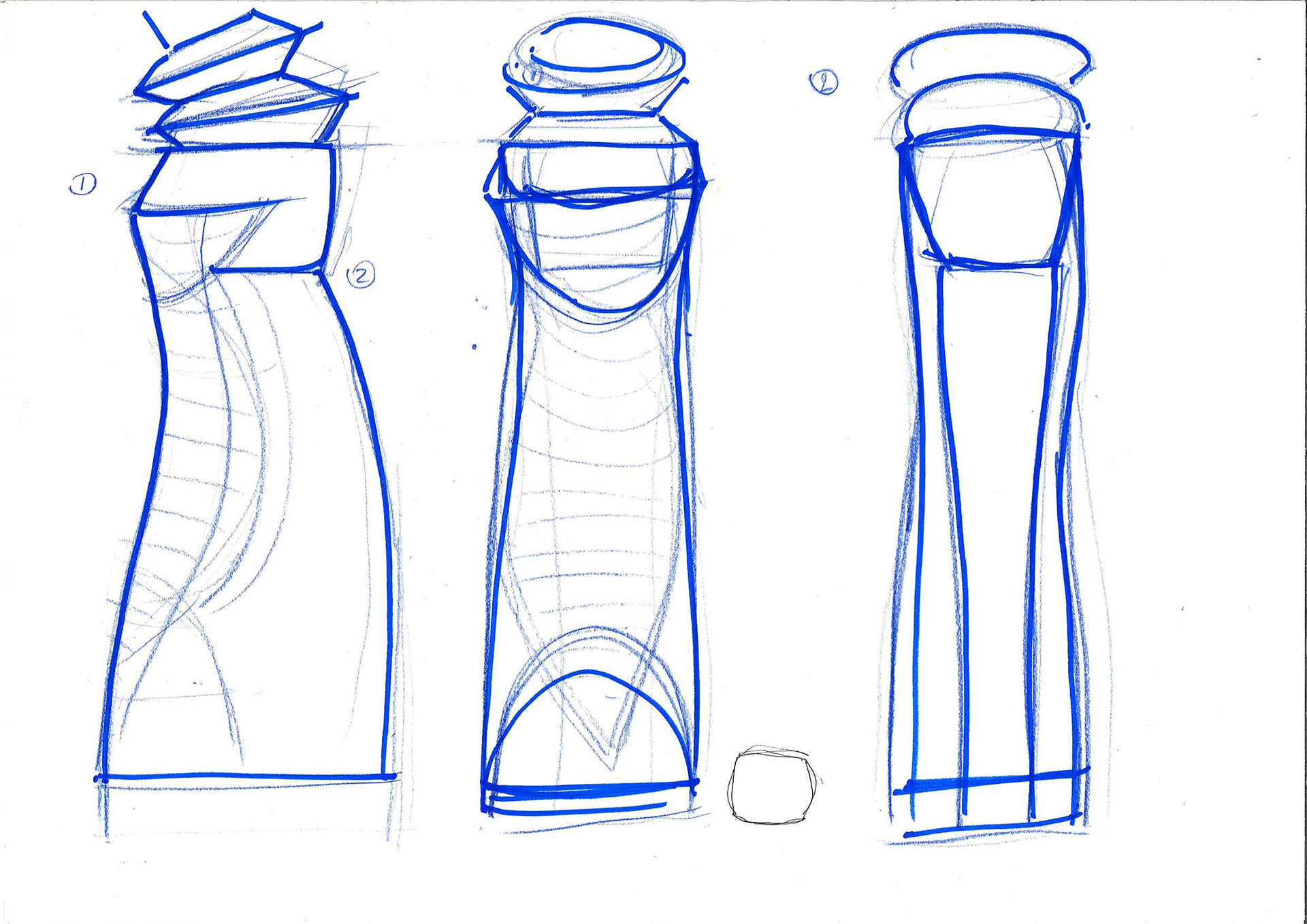

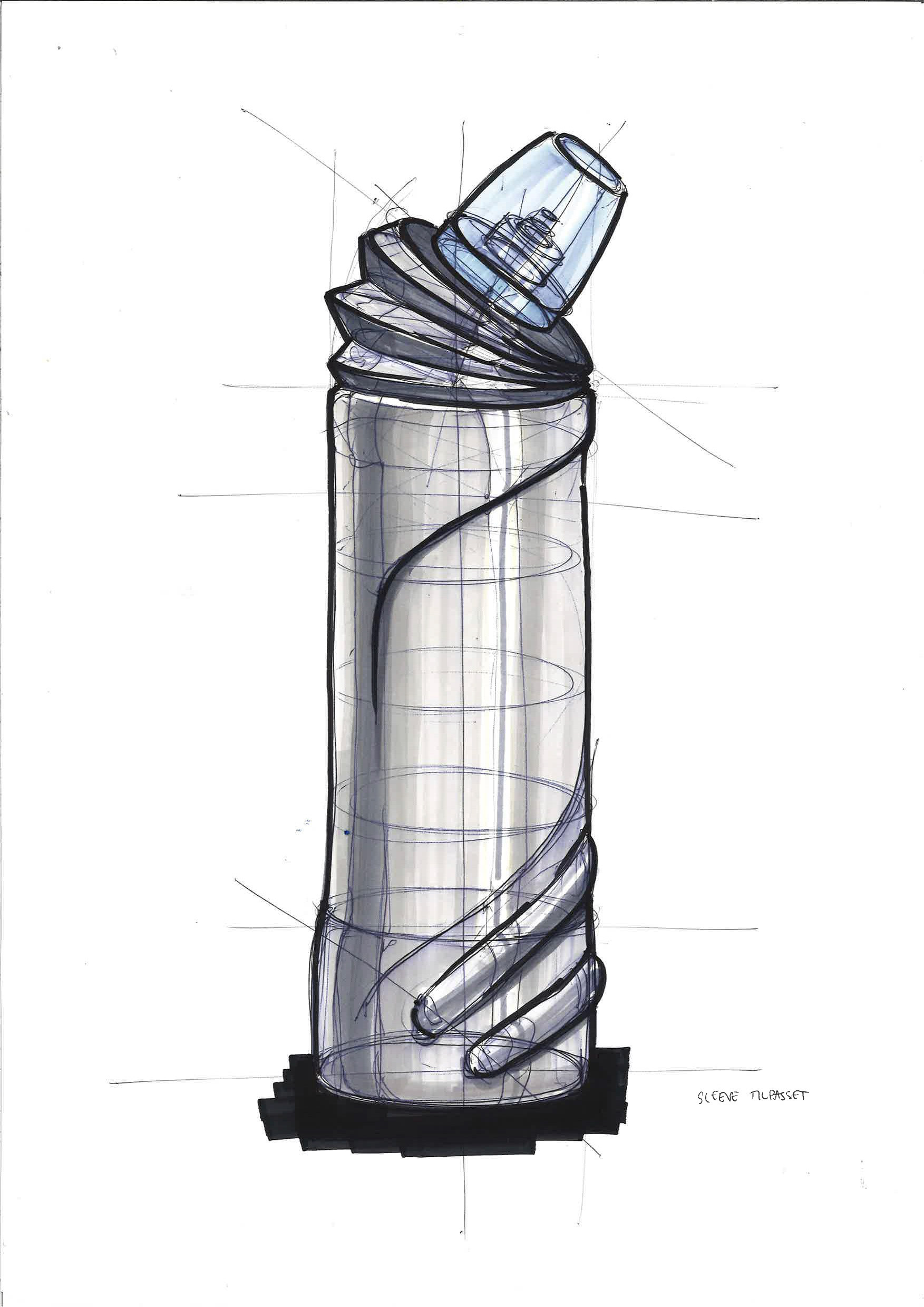

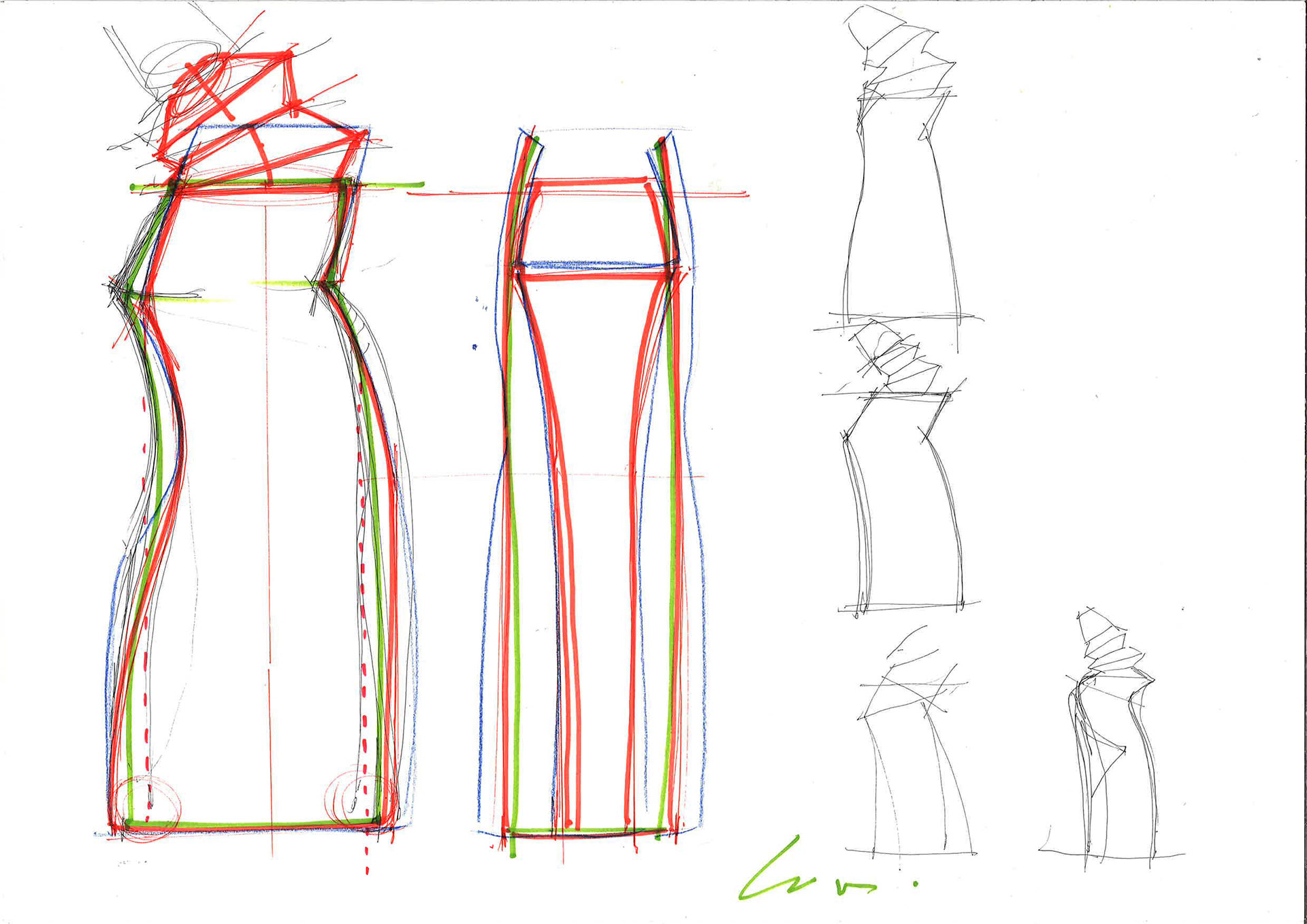

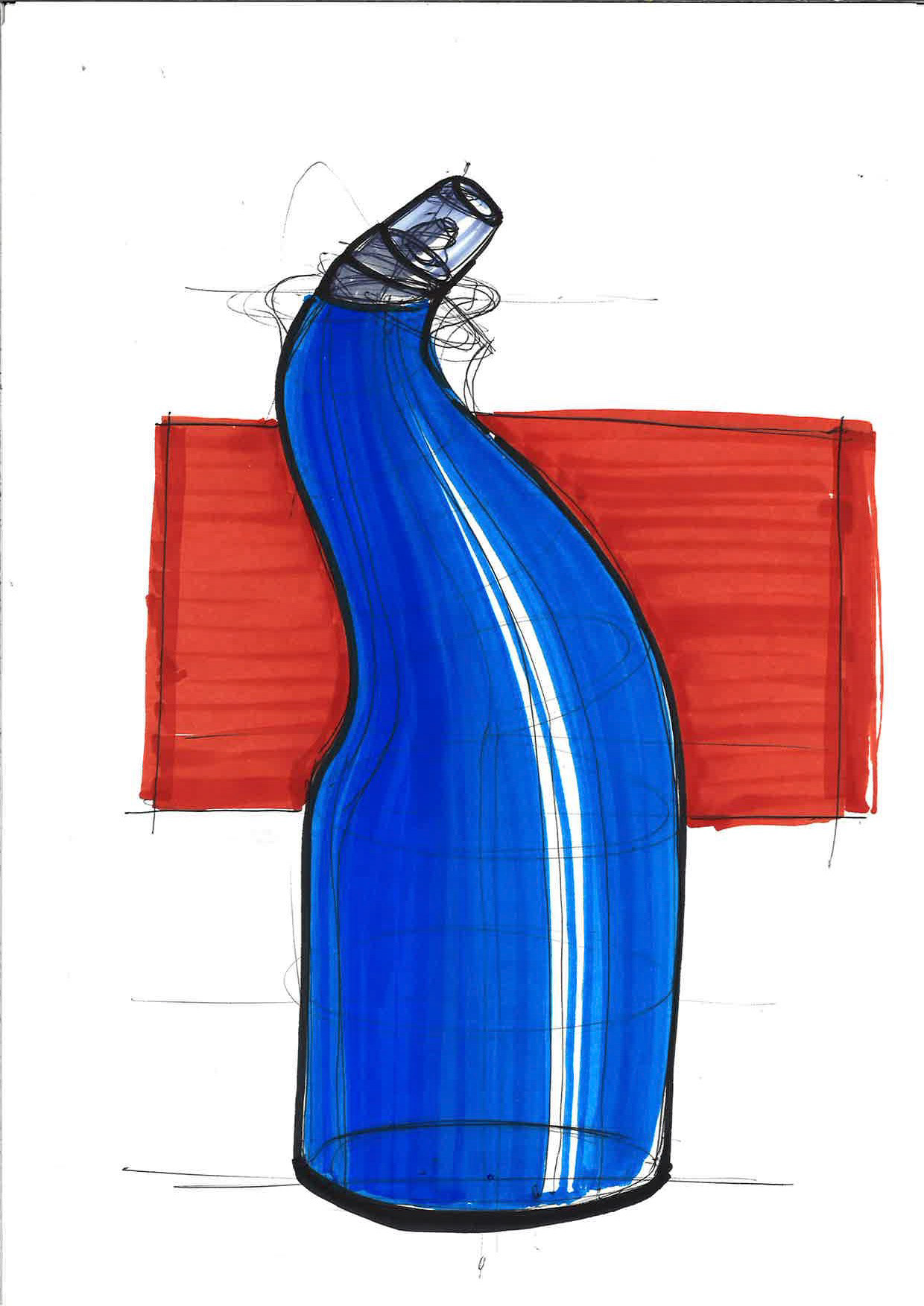

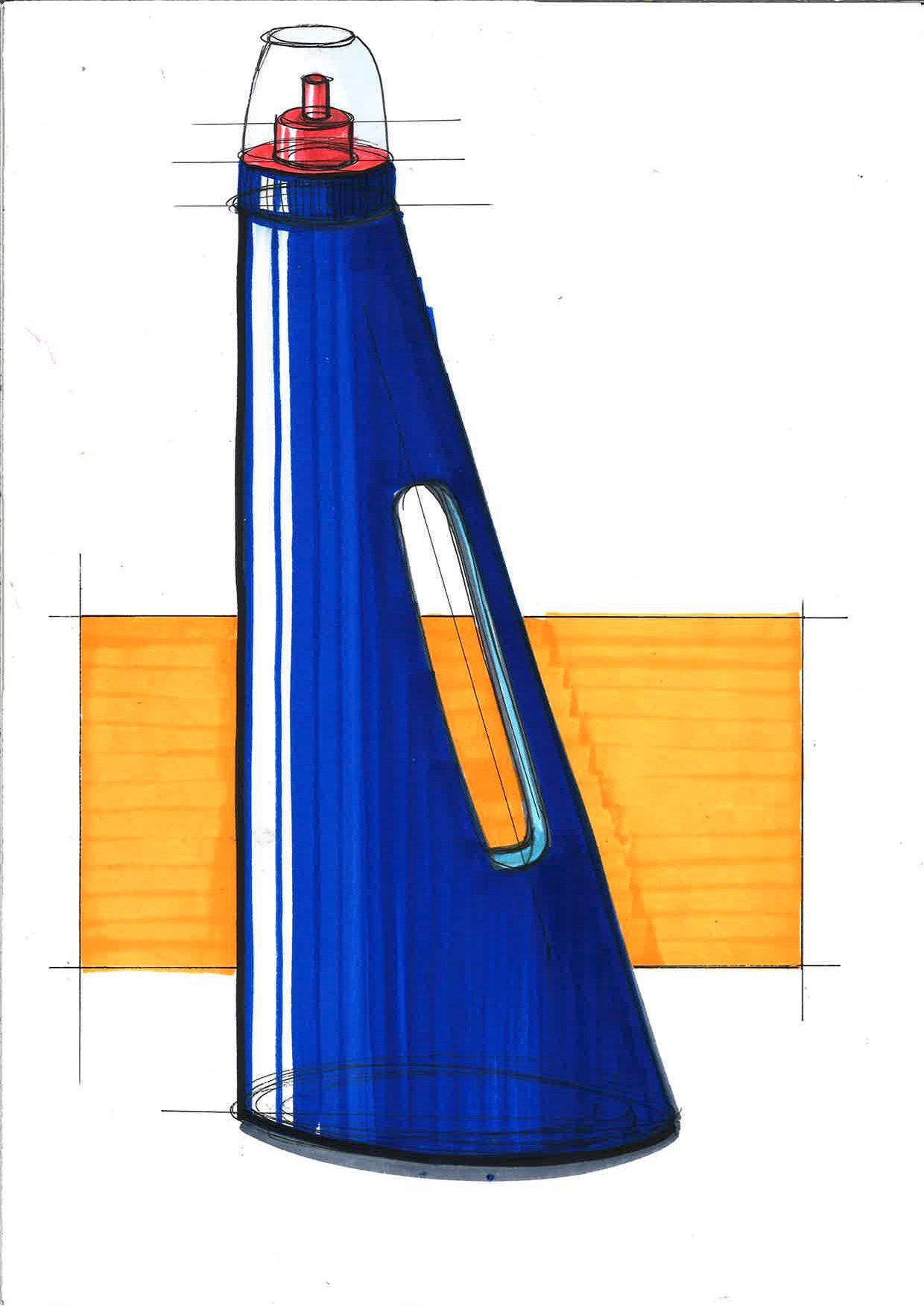

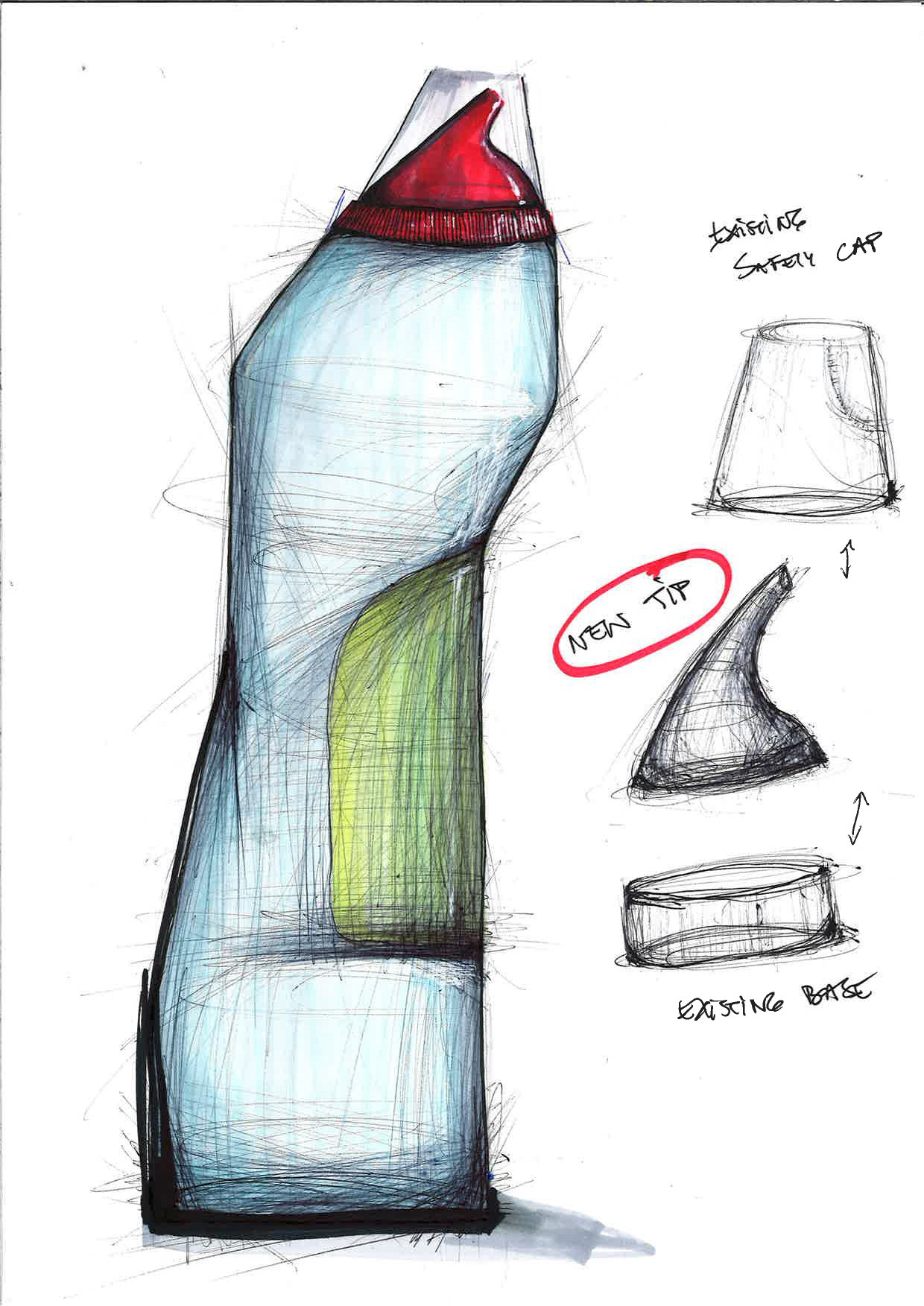

Early concept sketching

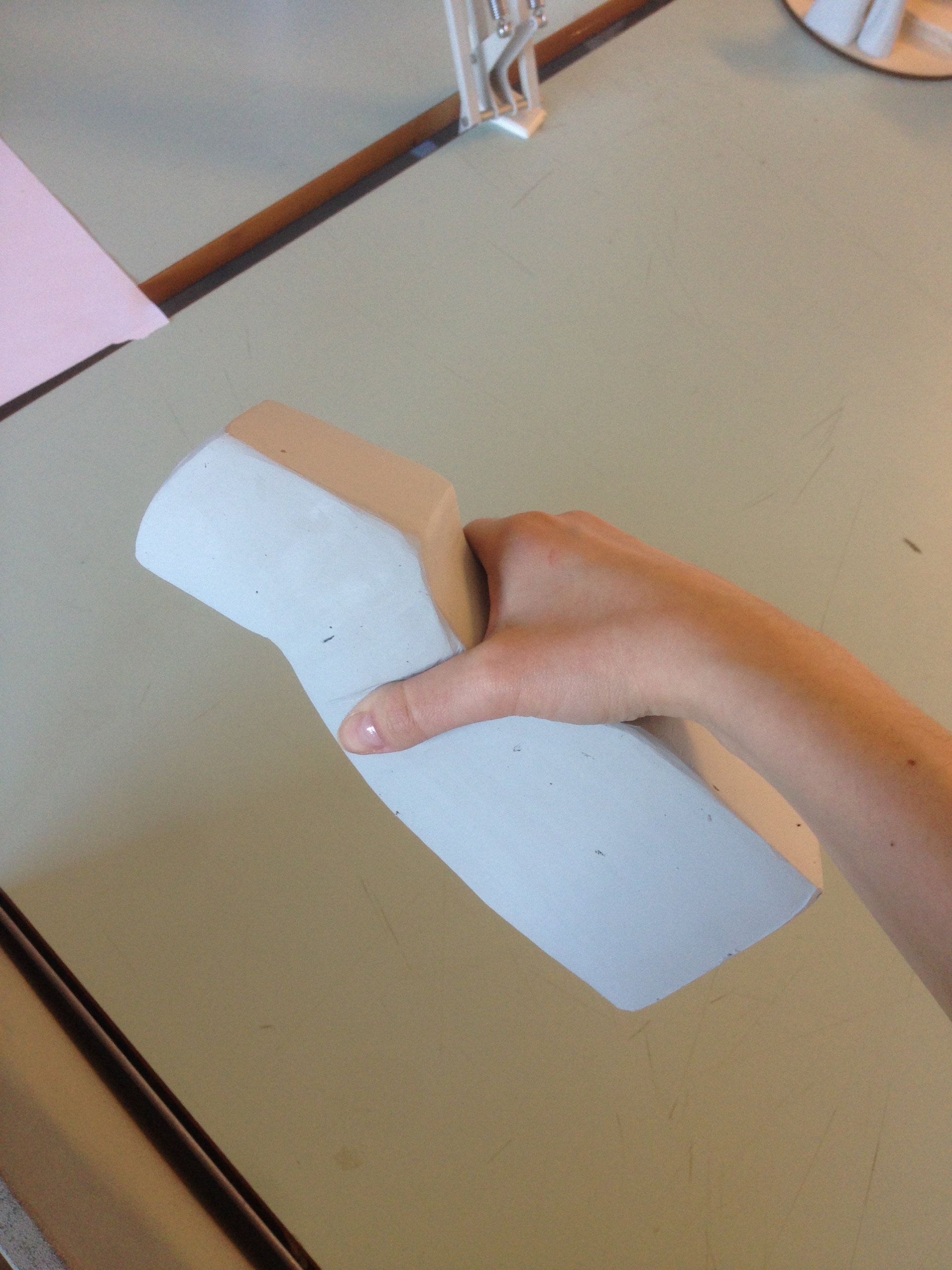

Clay modelling to test size, grip and design 1:1. The clay is shaped around a bottle so that the weight would be more accurate. In this way we could perform user studies with more valuable feedback.

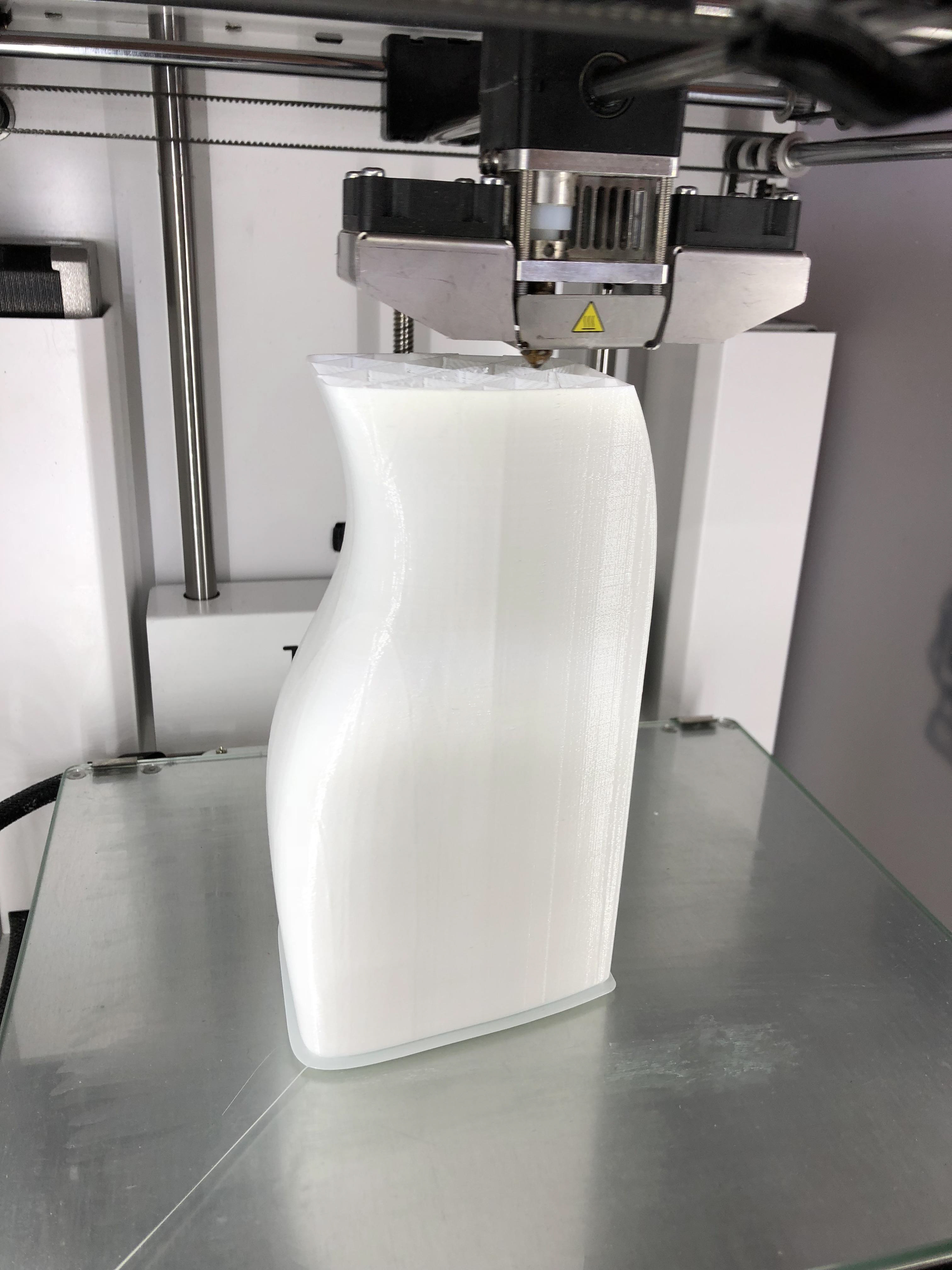

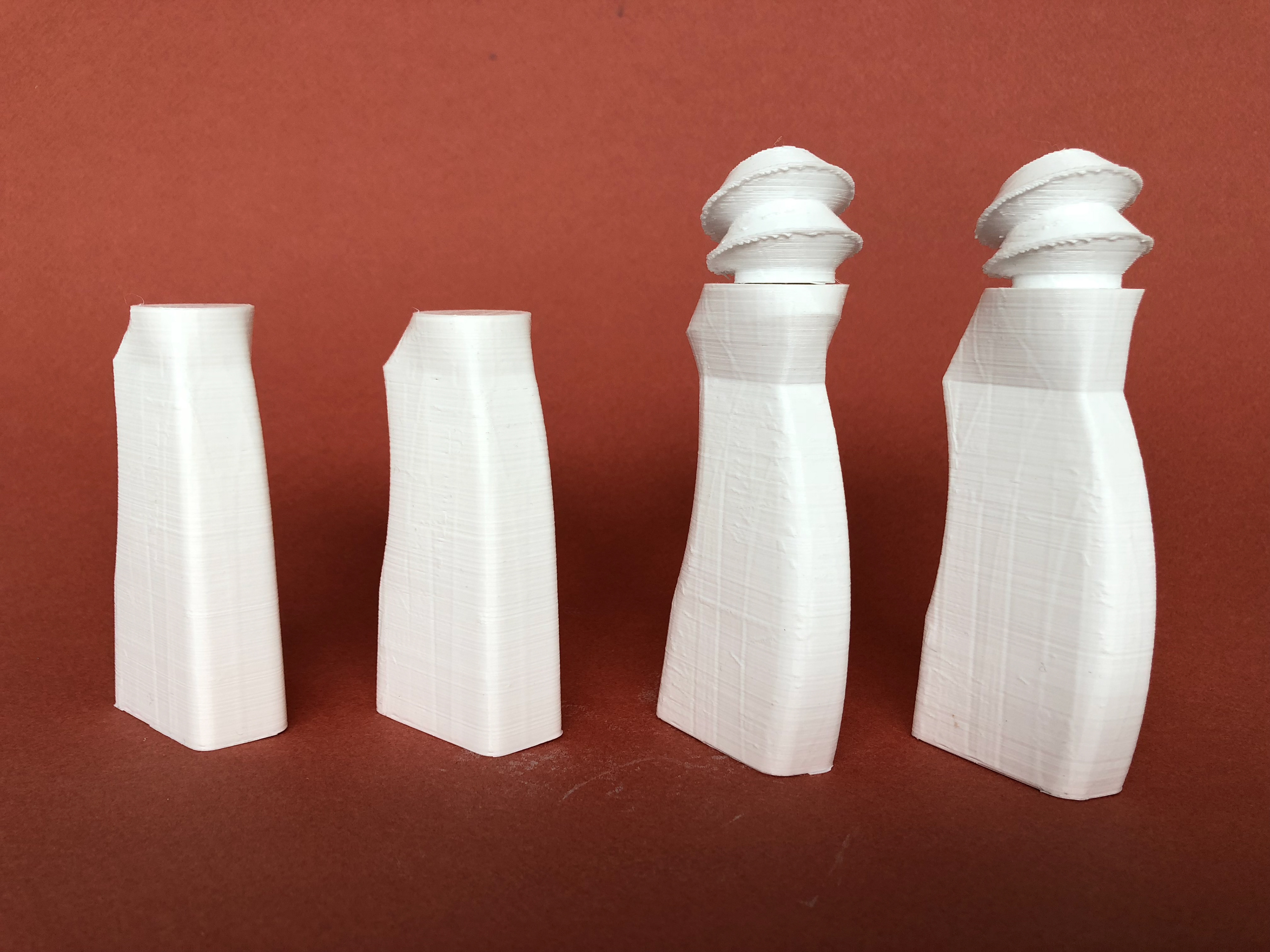

Rapid prototyping using 3D printing

This is some of the bottles that were produced using the manufacturing process "blow molding".